Skip to content

- Electromechanical integration of medium and low voltage system hardware

- Mechanical system layout

- Cabling and hydraulic routing

- Custom machine and waterjet part design

- Mechanical integration of industrial automation equipment

- Cost optimized die cast, sheet metal, injection molded frame variants

- Technical and part and development cost tradeoffs identified

- Define product minimal viable product for new customer market

- Mechanical product team lead

- Lead designer on all parts

- System assembly, sheet metal, injection molded plastic, cabling and harness

- AC-DC power supply integration

- Assembly and part drawing reviews (critical to function, key interfaces)

- Responsible for system level form, fit function

- Part and assembly tolerance analysis

- PCBA mechanical input, layout and technical review multiple internal CCAs)

- Works closely with digital and analog hardware engineering team to define V&V scope and test plan

- PCBA and OTS part thermal validation

- Shock and Vibration analysis

- HALT

- Part and assembly renders

- Feedback loop with marketing and product ownership team

- Created and maintained mechanical and system level across multiple design and validation engineers

- Tracked mechanical design and validation tasks and coordinated progress with multi-discipline team leads

- Part cost estimates in early design phase for different feature implementations

- Mechanical product team lead

- Lead mechanical designer

- System assembly, sheet metal, internal injection molded plastic, cabling and harness

- Assembly and part drawing reviews (critical to function, key interfaces)

- Responsible for system level form, fit function

- Part and assembly tolerance analysis

- Part first article validation (dimensional and cosmetic)

- PCBA mechanical input, layout and technical review (3 internal CCAs)

- Shared part design for subsequent chassis development (PXIe-1084, PXIe-1092)

- Created and maintained mechanical and system level development schedule for multiple variants.

- Tracked mechanical design and validation tasks and coordinated progress with multi-discipline team leads

- Part cost estimates in early design phase for different feature implementations

- Played key role in system cost reduction vs older variants

- Modular upgrade path for multiple chassis variant

- Single PCBA and mechanical interface design

- Field technician upgradable

- High speed customer internal (PCIe Gen3) internal cabling

- Modular mezzanine PCBA style design

- Flexible mechanical architecture for upgraded or different I/O designs

- High speed gen3 capable custom internal cabling

- Early prototype paper dolls and thermal evaluation

- Connector selection and I/O layout

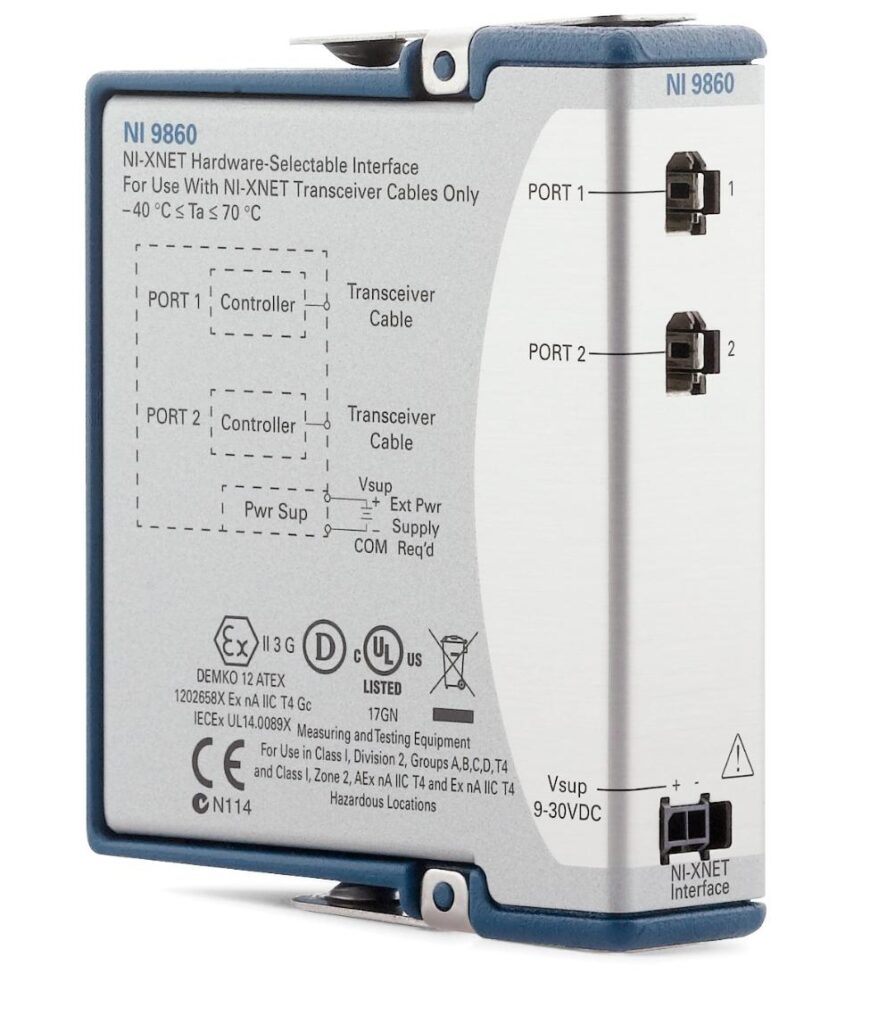

- Interchangable extensible cable design with multiple CAN interfaces: High Speed, Low Speed, LIN

- Modular cables share overmold on PCBA level design

- New c-Series side interface connector selection

- High voltage safety qualified

- -40 to 70C operational

- Custom test platform designed and validated with supplier

- Created internal thermal architecture specifications for thermally dissipative cables

- Passive dissipation architecture highly sensitive to low power applications

- Size, shape, mounting location requirements tested and defined

- NI c-Series automotive flexible CAN product

- Industrial ethernet connector validation

- PCBA mechanical layout and design:

- Safety isolation

- High density FPGA thermal evaluation

- High speed SAS storage drive ruggedization and validation

- MXI (x4 PCIe link) extension device

- Validated thermal and S&V to IEC 68-2-64 and IEC 68-2-27

- Buy/resell parted evaluation with in house validation

- Validation of partnered design with custom hardware upgrades

- Thermal validation of x64 architecture to match internal IEC 68-2-64 environmental requirements

- Validation of server ruggedization to IEC 68-2-27

- OTS hardware validation (Xeon, GPU, SSD, North/South bridge, power supplies, etc)

- Custom hardware bracketing for ruggedization

- Custom die cast handles

- Product markings and overlay updates to match National Instruments branding

- Paint/finish updates